3D printing has revolutionized the way we create and manufacture objects, but it is not without its challenges. Many beginners encounter issues that can be frustrating and time-consuming. In this guide, we will explore how to resolve common 3D printing problems effectively.

1. Poor Adhesion to the Build Plate

One of the most frequent issues faced by 3D printing enthusiasts is poor adhesion of the print to the build plate. This can lead to warping and failed prints. To resolve common 3D printing problems related to adhesion, consider the following:

- Ensure the build plate is clean and free from dust or grease.

- Adjust the nozzle height to achieve the correct distance from the build plate.

- Use adhesives like glue sticks or specialized sprays to enhance adhesion.

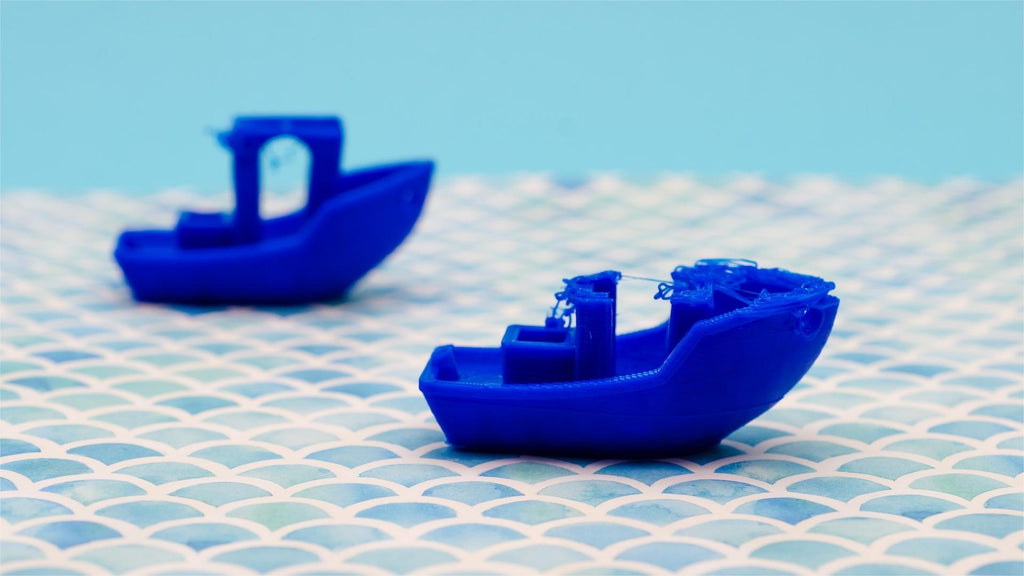

2. Stringing and Oozing

Stringing occurs when thin strands of filament are left behind as the print head moves between sections. This can be particularly annoying. To mitigate this issue, you can:

- Adjust the retraction settings in your slicer software.

- Increase the travel speed of the print head.

- Lower the printing temperature slightly to reduce filament flow.

3. Layer Misalignment

Layer misalignment can lead to unsightly prints and structural weaknesses. If you notice this issue, it might be due to mechanical problems or incorrect settings. Here are steps to resolve common 3D printing problems related to layer misalignment:

- Check the tightness of all belts and screws on your printer.

- Ensure that the stepper motors are functioning correctly.

- Calibrate the printer regularly to maintain accuracy.

4. Inconsistent Extrusion

Inconsistent extrusion can result in gaps and uneven surfaces on your prints. This problem can often be traced back to the filament or the extruder. To address this, consider:

- Using high-quality filament to ensure consistent diameter.

- Cleaning the nozzle to prevent clogs.

- Adjusting the extrusion multiplier in your slicer settings.

5. Overheating and Melting

Overheating can cause prints to sag or lose detail. If you find that your prints are melting, it may be due to incorrect temperature settings or environmental factors. To resolve common 3D printing problems related to overheating, you can:

- Lower the printing temperature in your slicer settings.

- Ensure adequate cooling with fans or by adjusting the print speed.

- Print in a controlled environment to avoid temperature fluctuations.

By understanding these common issues and their solutions, you can significantly improve your 3D printing experience. For a more comprehensive troubleshooting guide, visit  .

.

In conclusion, while 3D printing can present challenges, being aware of common problems and their solutions can enhance your skills and results. Happy printing!